| Thickness mm |

Width mm |

Lenfth mm |

Volume m3 |

| 180 | 250 | 2750 | 0,1237 |

| Description | Minimal | Planned |

| Pine and cedar sleepers | 79 | 96 |

| Spruce and fir sleepers | 90 | 105 |

| Description | Impregnation depth | |

| By sapwood

мм |

On sound or ripe wood,

мм |

|

| Pine and cedar sleepers | No less then 5 | No less then 5 |

| Spruce, fir and larch sleepers | No less then 5 | No less then 5 |

| Thickness, mm |

Depth, mm |

Length, mm |

Volume, mm |

| 160 | 230 | 2750 | 0,101 |

| Description | Minimal | Planned |

| Pine and cedar sleepers | 79 | 96 |

| Spruce and fir sleepers | 90 | 105 |

| Description | Impregnation depth | |

| By sapwood,

mm |

By sound or ripe wood,

m |

|

| Сосновые и кедровые шпалы | at least 5 | at least 5 |

| Spruce, fir and larch sleepers | at least 5 | at least 5 |

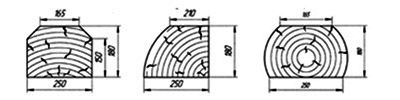

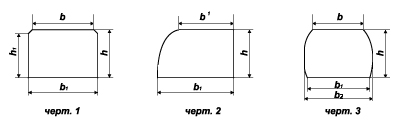

| Type | Thickness | Depth h | The width of the top layer b | Beam Width with Unsawn Sides b2 | The height of the sawn sides of the cut timber h1 | ||

| Broadened | Wide | Normal | |||||

| Type I | 180 | 220 | 200 | --- | 260 | 300 | 150 |

| Type II | 160 | 220 | --- | 175 | 250 | 280 | 130 |

| Type III | 160 | --- | 200 | 175 | 230 | 260 | 130 |

| Name of track superstructure material | Purpose | |

| Wooden bars for turnouts: | ||

| Edged, Unedged |

Type I - for main tracks Type II - for low-density main, receiving and departure routes and sorting. Type III - for access roads of industrial enterprises. |

|

|

Sets of wooden beams for turnouts (according to GOST

8816-70) |

||||||||||||||||

|

Bars length, m |

Designation of a set of bars |

|||||||||||||||

|

A1 |

A2 |

A3 |

A4 |

A5 |

Б1 |

Б2 |

||||||||||

|

Rail type |

Cross turnouts translations |

|||||||||||||||

|

Р65 |

Р65, Р50 |

Р65 |

Р50, Р43 |

|||||||||||||

|

Marks of turnouts |

||||||||||||||||

|

1/22 |

1/18 |

1/11 |

1/9 |

1/11 |

1/9 |

|||||||||||

|

The number of bars in a set with their

division along the width of the upper plate on B-broadened, W-wide, N-normal |

||||||||||||||||

|

B |

W |

B |

W |

B |

W |

B |

W |

B |

N |

B |

Н N |

B |

N |

|||

|

3,00 |

16 |

- |

22 |

9 |

16 |

- |

15 |

2 |

16 |

- |

17 |

- |

- |

- |

|

3,25 |

14 |

25 |

2 |

14 |

- |

10 |

- |

10 |

1 |

7 |

- |

7 |

- |

- |

|

3,50 |

5 |

16 |

5 |

12 |

- |

8 |

- |

8 |

- |

7 |

- |

7 |

19 |

- |

|

3,75 |

- |

16 |

- |

12 |

- |

7 |

- |

4 |

- |

8 |

- |

5 |

18 |

- |

|

4,00 |

- |

14 |

- |

11 |

- |

5 |

- |

6 |

- |

4 |

- |

3 |

8 |

- |

|

4,25 |

- |

12 |

- |

9 |

4 |

2 |

4 |

1 |

6 |

- |

3 |

1 |

8 |

- |

|

4,50 |

- |

10 |

- |

8 |

6 |

1 |

5 |

1 |

7 |

- |

7 |

- |

10 |

- |

|

4,75 |

- |

10 |

- |

9 |

- |

6 |

- |

4 |

2 |

3 |

3 |

1 |

4 |

4 |

|

5,00 |

- |

11 |

- |

9 |

- |

5 |

- |

4 |

- |

5 |

- |

5 |

- |

8 |

|

5,25 |

- |

10 |

- |

8 |

- |

6 |

- |

4 |

- |

6 |

- |

4 |

- |

8 |

|

5,50 |

- |

11 |

- |

7 |

- |

4 |

- |

- |

- |

3 |

- |

- |

4 |

- |

|

ИТОГО |

35 |

135 |

29 |

108 |

26 |

54 |

24 |

44 |

32 |

43 |

30 |

33 |

71 |

20 |

|

ВСЕГО |

170 |

137 |

80 |

68 |

75 |

63 |

91 |

|||||||

|

Set volume m³ |

32,77 |

26,00 |

15,46 |

12,55 |

12,39 |

10,07 |

16,10 |

|||||||

|

Weight of one

set, t |

19,0 |

15,1 |

9,0 |

7,3 |

7,2 |

5,9 |

9,4 |

|||||||